3F’s Pharma Division

-

3F LuboMag

3F LuboMag -

3F LuboCal

3F LuboCal -

3F LuboStear

3F LuboStear -

REFINED GLYCERIN

REFINED GLYCERIN

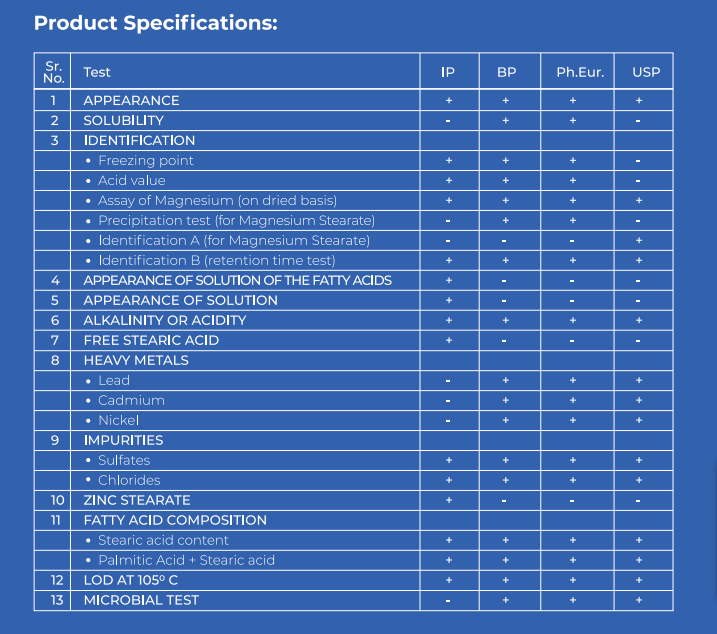

3F LuboMag Magnesium Stearate

3F LuboMag is one of the most desirable lubricating agents used in solid dosage formulations. it is safe and non-toxic in nature.

Applications:

Pharmaceutical industry, Food, Nutraceutical & Cosmetic formulations as lubricant, anti-adherent, anti-caking agents, binder, emulsifier, etc.

-

Pharmaceutical Industry

-

Food

-

Neura

-

Tyre & Rubber Grades

-

High Titre & Metal Powder Grades

-

Other Speciality Grades

Packaging: 25 kgs net weight packed in Paper Bags / HDPE Drums with LDPE inner liners.

3F LuboCal Calcium Stearate

3F LuboCal, Calcium Stearate is a safe and non-toxic lubricating agent and water repellent, being the product of choice in many solid dosage formulations.

Applications:

Pharmaceutical industry, Food, Nutraceutical & Cosmetic formulations as lubricant, mould release agent, anti-tack agent, anti-caking agents, emulsifier, etc.

-

Pharmaceutical Industry

-

Food

-

Neura

-

Tyre & Rubber Grades

-

High Titre & Metal Powder Grades

-

Other Speciality Grades

Packaging: 25 kgs net weight packed in Paper Bags / HDPE Drums with LDPE inner liners.

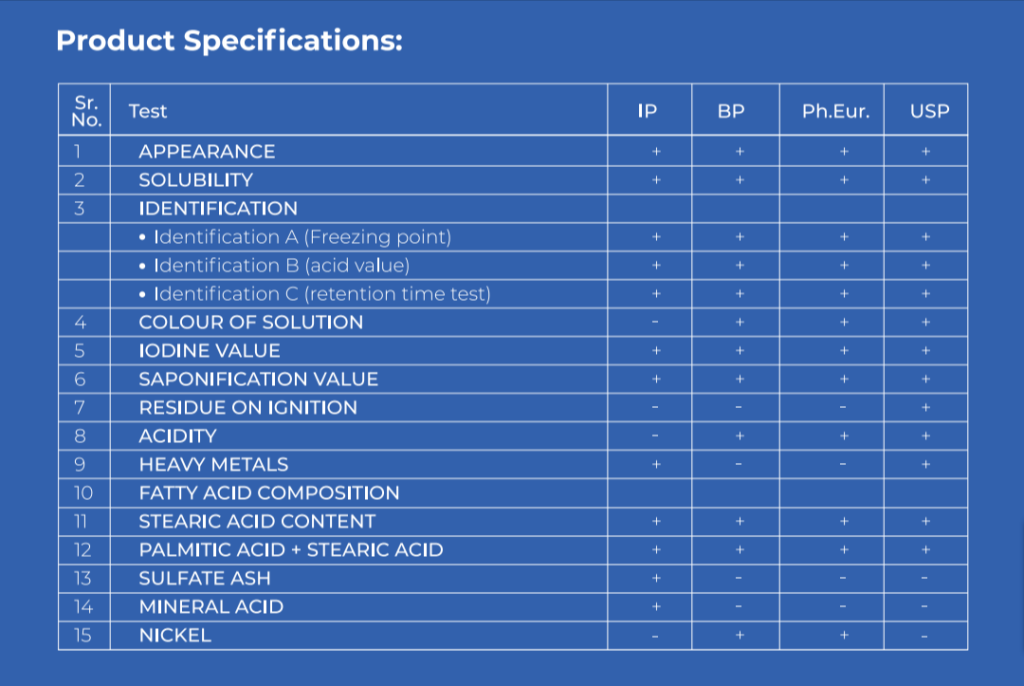

3F LuboStear Stearic Acid

3F LuboStear, Stearic Acid is a safe and non-toxic lubricant and controlled release agent used in solid dosage and skin care formulations.

Applications:

Pharmaceutical industry, Food, Nutraceutical & Cosmetic formulations as lubricant, anti-adherent, anti-caking agent, binder, emulsifier, etc.

Packaging: 25 kgs net weight packed in Paper Bags / HDPE Drums with LDPE inner liners.

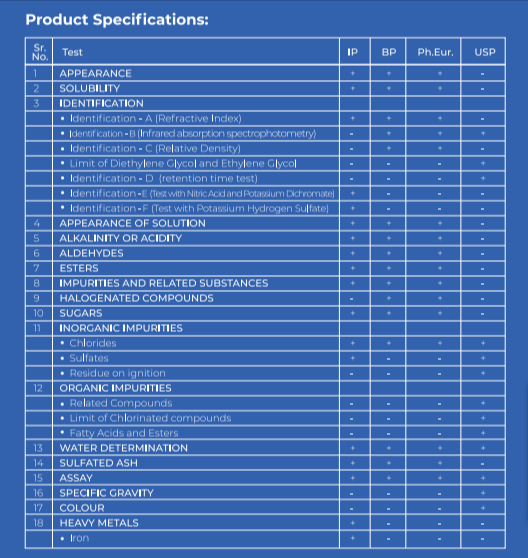

Refined Glycerin - Pharma Grade

Refined Glycerin is odourless and colourless. Its multi-functional properties and non-toxic nature make it a versatile product which is extensively used in pharmaceutical products, personal care and cosmetics.

Our quality grade meets both domestic and international regulatory requirements including that of the Pharmacopeia and Food Safety and Standards Authority of India.

Applications:

Refined Glycerin is used in pharmaceutical industries as lubricant, thickener, demulcent, humectant, and sweetener. It is commonly used in expectorants, suppositories and gel capsules.

-

Pharmaceutical Industry

-

Food

-

Neura

-

Tyre & Rubber Grades

-

High Titre & Metal Powder Grades

-

Other Speciality Grades

Packaging: Bulk in Tanker Load/Flexi Tank & 250 kgs net weight in new HDPE Drums

Our Certifications

BAKER'S CLUB MEET - PHOTOS

Do You Have Any Questions? Feel Free To Contact Us.

QUICK LINKS

ACCOUNTS

TERMS & CONDITIONS

Proudly Designed and Developed By Artrix Tech PVT LTD